HT-DESI-MS Facility: Workflow and Systems

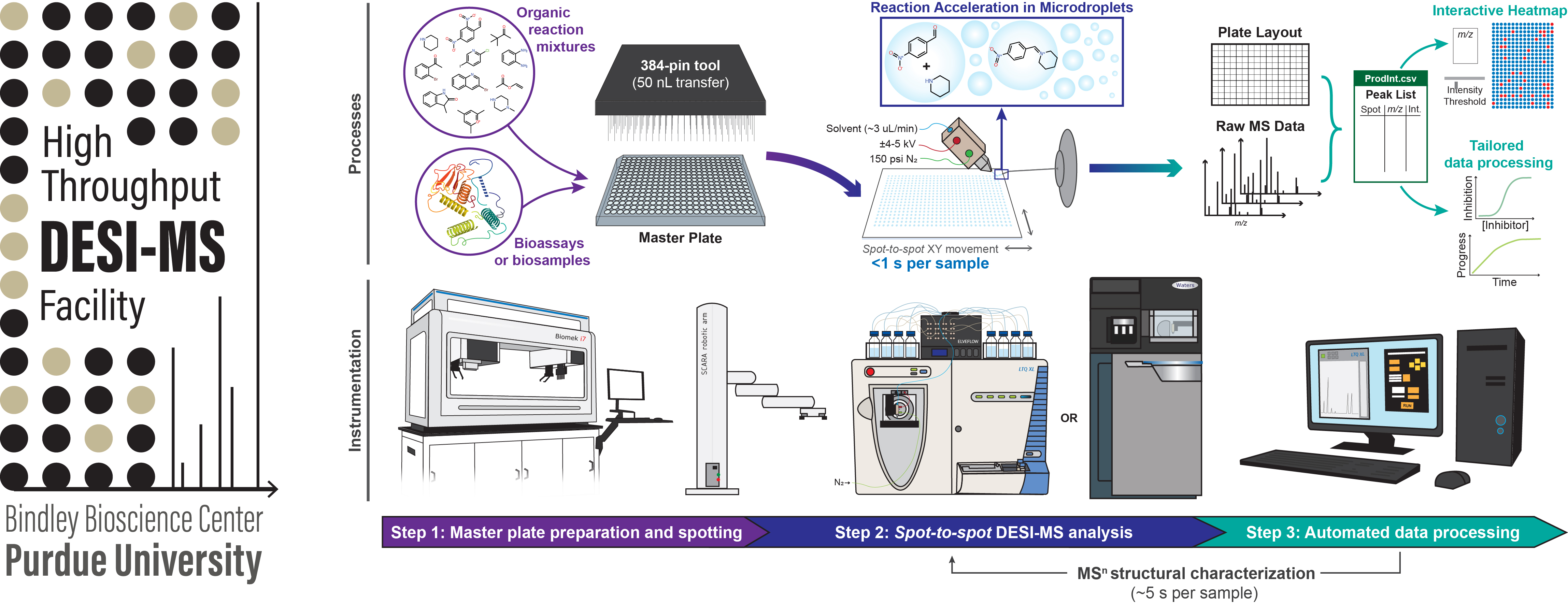

Generally, three main steps are followed on a HT-DESI-MS experiment. Namely:

- Fluid-handling robotics are used to automatically prepare one or more 384-well plates and spot them onto a PTFE-coated glass slide in arrays of up to 6,144 samples. These arrays can include exclusively unique samples or a number of technical replicates from each independent well. Typically, experiments are run at 1,536-spot densities including 4 technical replicates per well plate. Arrays are generated using a 384-pin tool calibrated for 50 nL transfers. Spotted slides are then automatically transferred to a DESI stage.

- HT-DESI-MS (synthesis/)analysis is carried out directly from the spotted slides at a throughput in the order of 1 Hz. Screening takes place following a fully automated spot-to-spot motion controlled by custom software. DESI is typically carried out using methanol or acetonitrile as spray solvents, however the DESI solvent selection is customizable. If required, online structural analysis can be carried out from the same spotted slide via tandem MS (ca. 5 seconds per sample).

- Data analysis takes place automatically via raw data parsing, scan averaging, spot assignment and any further processing required for the specific application. Common custom data analysis settings includes spot and well averaging, filtering, lock mass correction, calculation of ion intensity ratios, absolute quantiation using external calibration curves, and comparison with control wells. Most data analysis is typically targeted (i.e. using known m/z values) although untargeted options are also available.

There are three generations of the HT-DESI-MS technology available through the facility. Typically, which generation to use will depend on the particular application. Click below to learn more about each generation.

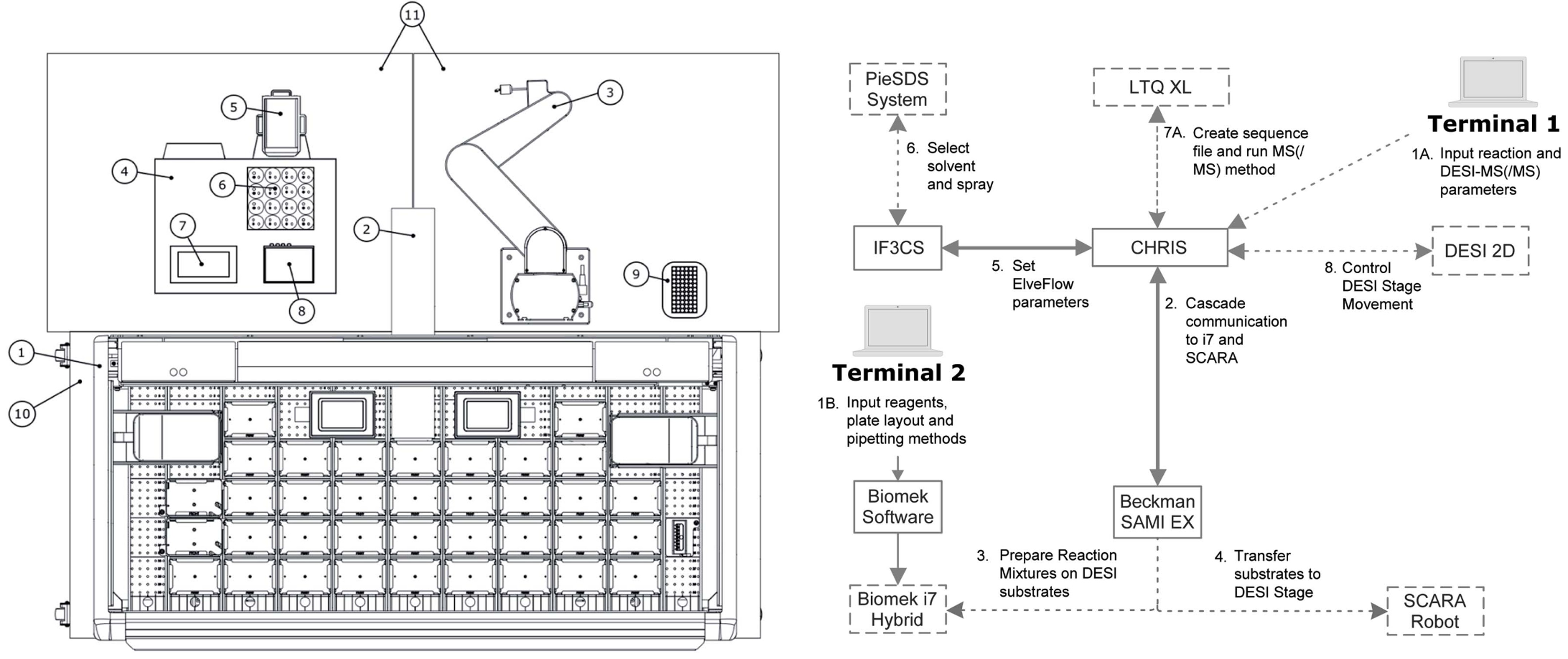

The first generation of the HT-DESI-MS technology was built under the DARPA Make It program. It consists of both custom and commercial hardware and software. Commercial instrumentation includes:

- Biomek i7 liquid handling workstation (Beckman Coulter) equipped with a 50 nL pin tool (V&P Scientific).

- PF3400 SCASelective Compliance Articulated Robot Arm (SCARA; Precise Automation) for plate transfer.

- LTQ XL ion trap mass spectrometer (Thermo Scientific)

- DESI 2D ion source (Prosolia).

Additional capabilities for on-the-fly solvent switching are available through a custom solvent delivery system developed at Purdue with Elveflow technology. The platform is controlled using a custom Python-based software termed CHRIS which coordinates the individual instruments software. A detailed description of the hardware and software of this platform can be found here.

This system is routinely used for organic reaction screening and tandem MS, especially multi-stage (MSn), experiments. Below is a demonstration of the platform utilization for a reaction screening campaign.

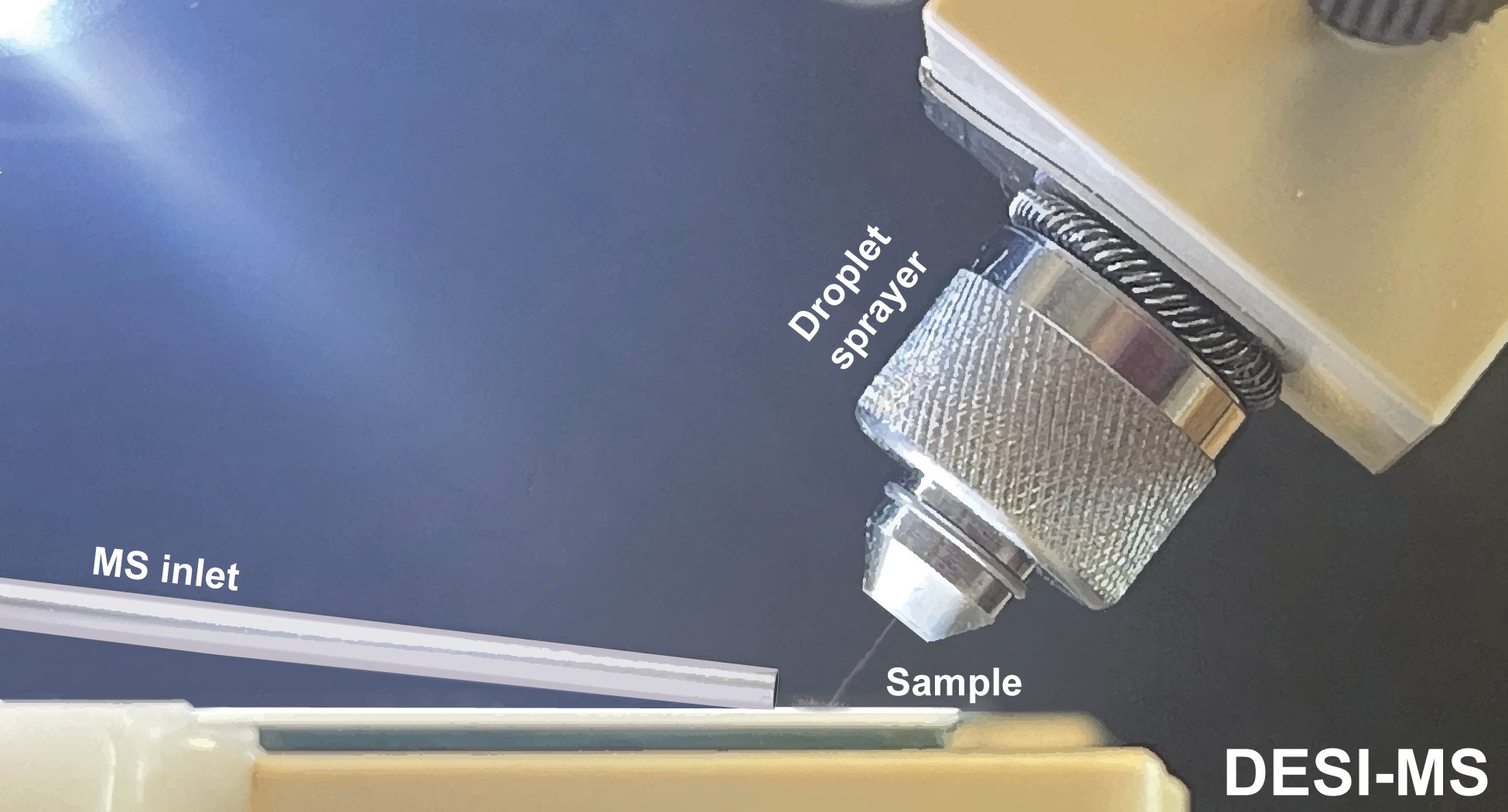

Through a collaboration with Waters Corporation, the first generation HT-DESI-MS platform was extended to a second mass spectrometer: a Synapt G2-Si quadrupole time-of-flight (Waters) which provides capabilities for integration with Traveling Wave Ion Mobility Spectrometry (TWIMS). This instrument is equipped with a 2D DESI stage that includes a XS-generation DESI sprayer (shown below) and a prototype heated transfer line (Waters), both of which provide increased robustness and higher ion fluxes, improving the overall performance of HT-DESI-MS.

This system is routinely used for higher-sensitivity applications including biological sample screening and biological assays.

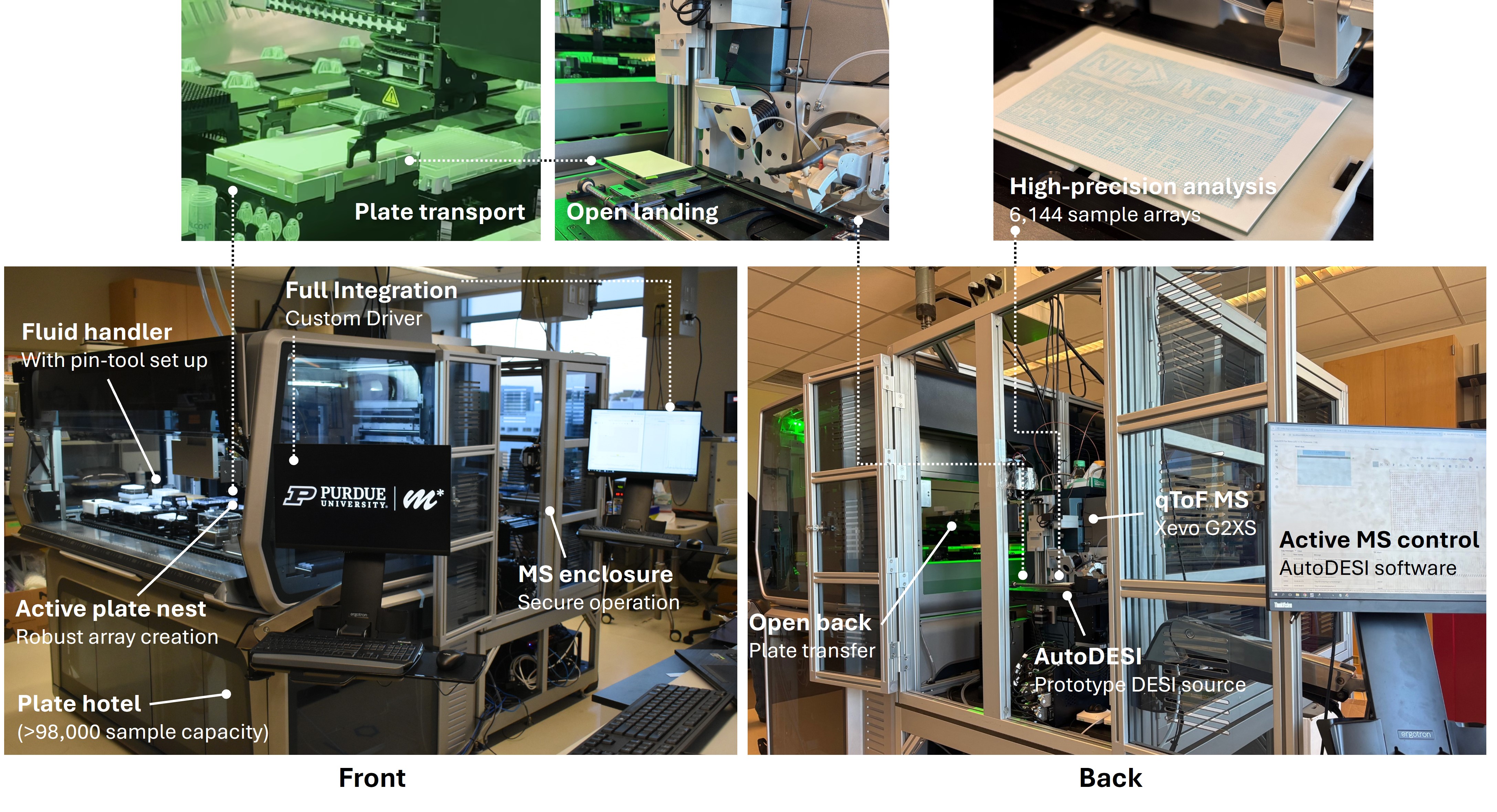

The second generation of the HT-DESI-MS technology was developed as part of the NCATS ASPIRE program in collaboration with Waters Corporation and Hamilton Robotics. It was built following a similar logic to that of the first-generation system but with increased robustness, simpler operation, improved integration and automation, faster data analysis, and extended sample capacity. The system is consists of:

- Vantage 2.0 fluid handling workstation (Hamilton) equipped with a 50 nL pin tool (V&P Scientific) and on-deck accessories for pin tool automation, an entry/exit device that extends the platform capacity up to ~100,000 samples per experiment, and a track gripper that provides flexible hardware integration via multi-point plate transfer.

- Xevo G2-XS quadrupole time-of-flight mass spectrometer (Waters).

- Prototype AutoDESI source developed in collaboration with Waters, together with DESI XS sprayer and a custom-built heated transfer capillary. The source and its control software provide flexibility on the platform throughput which can be as high as 3 samples per second.

The entire system follows an easy-to-trigger worklist-driven workflow. Worklists, which control all the experiment parameters, can be generated anywhere and then simply imported into the platform for the experiment run.

The entire system follows an easy-to-trigger worklist-driven workflow. Worklists, which control all the experiment parameters, can be generated anywhere and then simply imported into the platform for the experiment run.

This system is routinely utilized for drug discovery activities, including both synthesis and analysis projects. Synthesis is facilitated by a prototype nanoscale droplet collection module (see Capabilities for details) that can be easily integrated with the HT-DESI-MS platform.

Hall for Discovery and Learning Research

207 S. Martin Jischke Dr. - Room 415

Purdue University

West Lafayette, IN 47907