High Throughput Synthesis and Analysis

We are developing a system for the high-throughput screening of organic reactions. This system combines a liquid-handling robot for rapid reaction mixture preparation with desorption electrospray ionization (DESI) for fast reaction mixture analysis. This combination results in a screening system capable of analyzing thousands of organic reactions per hour.

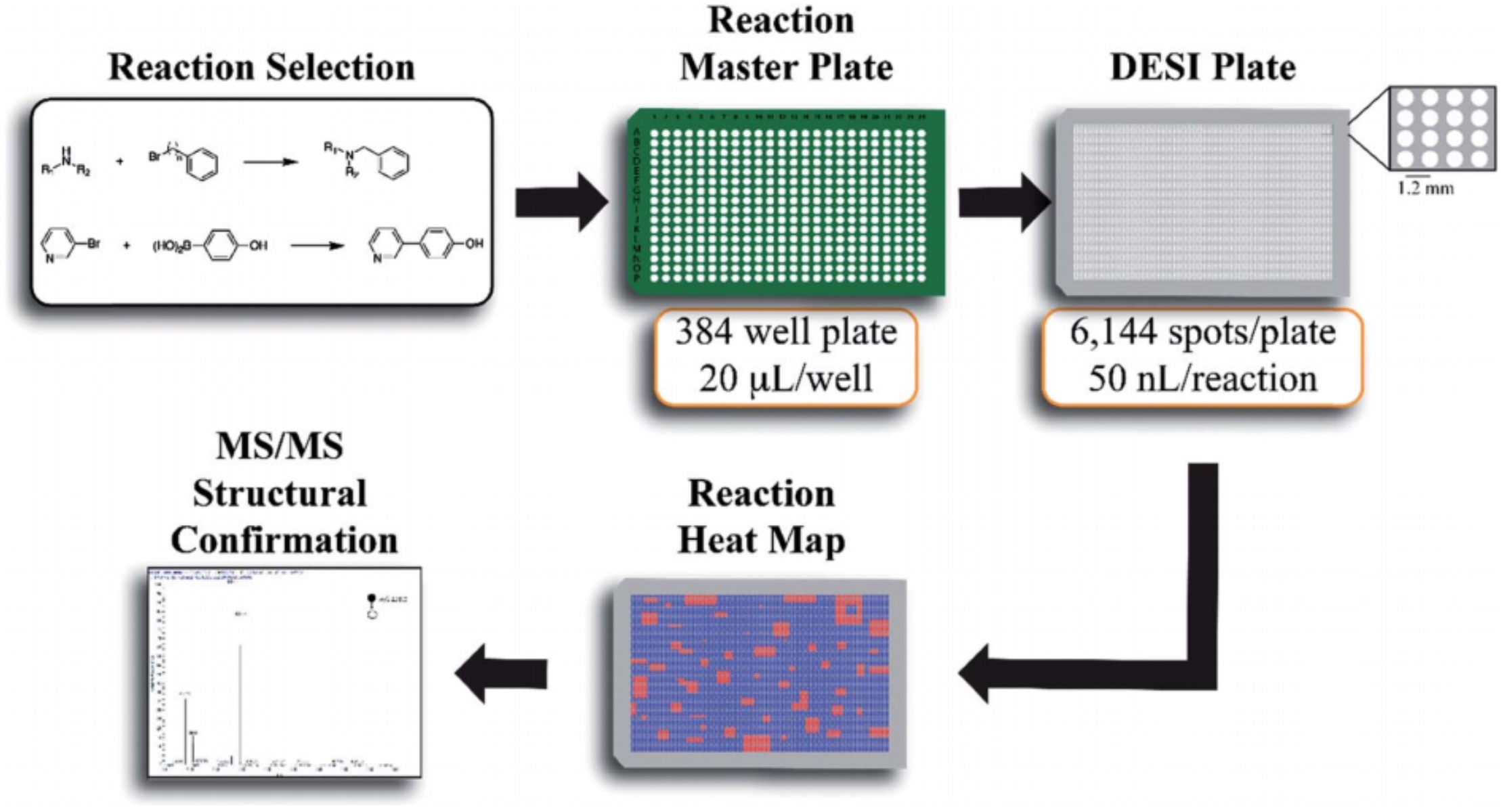

Figure 1. Summary of the high throughput reaction screening experiment workflow with DESI-MS. Both the master plate and the DESI plate are prepared in an automated fashion with a liquid handling robot. The DESI plate (porous PTFE) is prepared with a 50 nL pin tool.

Figure 1 provides a summary of the experiment. Reaction mixtures are combined in 384-well microtiter plates using a liquid handling robot. Each individual well of the microtiter plate represents a unique reaction condition, in which the reagents used, reaction solvent, stoichiometry, catalyst, ligand, etc. can all be varied.

Samples of the reaction mixtures are then transferred to a PTFE surface. This surface is prepared by covering a glass slide, which has the footprint of a traditional microtiter plate, with a layer of porous PTFE. This transfer of the reaction mixtures is accomplished by using a pin tool, which is an array of 384 stainless steel pins which are designed such that they transfer a volume of 50 nL. The pin tool is dipped into the microtiter plate containing the reaction mixtures and then placed onto the PTFE surface leaving behind spots of reactions mixtures which are approximately 1 mm in diameter. Up to 15 additional 384-well plates can be spotted onto one PTFE surface by slightly offsetting the location of the pinning each time resulting in total of 6,144 unique reaction conditions on one plate.

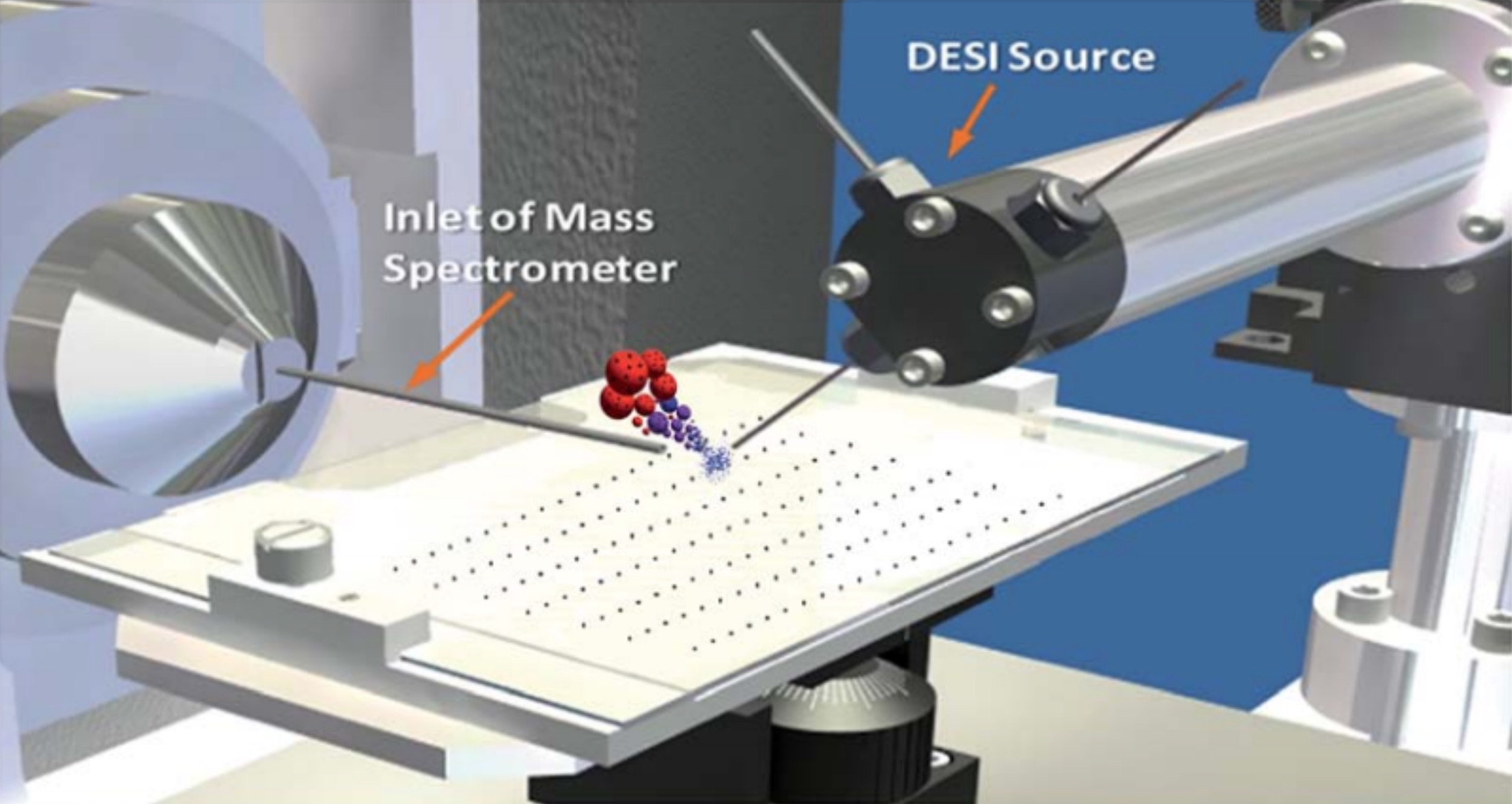

Figure 2. Reaction (in secondary droplets) and MS product analysis of reaction mixtures presented in microtiter plate format.

The reaction mixtures are placed onto a surface to facilitate the DESI analysis (Figure 2). Since DESI is a technique in which analytes are desorbed from a surface, the reaction mixture must be on a surface on order to perform DESI. With an analysis time of less than two seconds per spot, DESI provides reaction information at a rate that far exceeds techniques such as LC/MS.

DESI allows for rapid analysis, but it also offers the opportunity of accelerated synthesis. During DESI both thin films are microdroplets are created, and these are environments in which accelerated organic reactions have been observed. When synthesis occurs during analysis, additional steps such as long incubation periods are unnecessary further increasing the throughput of the system.

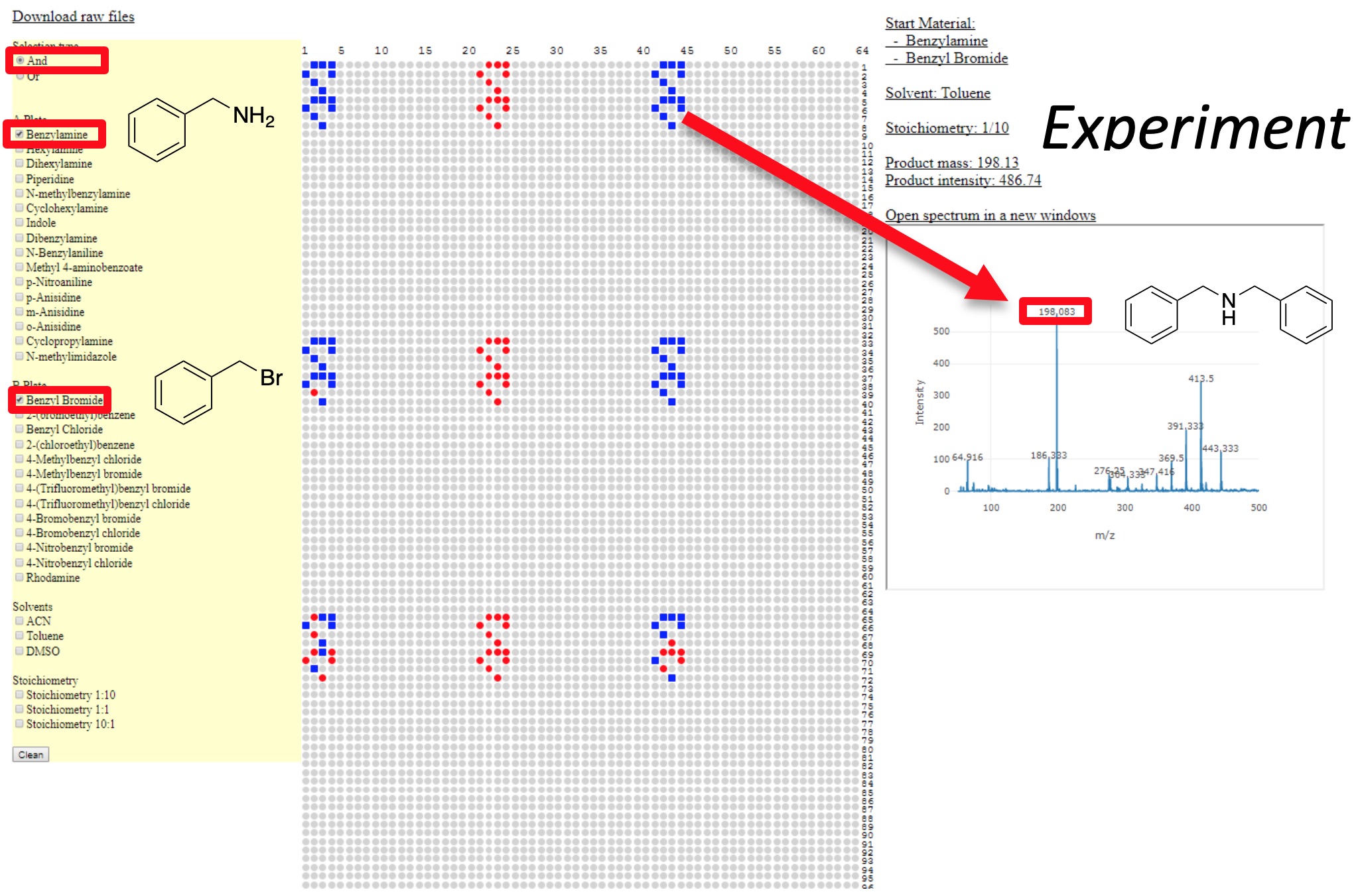

In order to handle the large data loads that a system such as this generates, we have developed custom software which provides an interface through which chemists can quickly analyze the data from an experiment (Figure 3). Once an experiment is complete, additional information such as product confirmation and byproduct identification can be obtained by returning to individual spots and performing MS/MS analysis.

Figure 3. Custom built software which allows for the immediate visualization and analysis of reaction screening data.

Using this system, we have screened amine alkylation, acylation, and sulfonylation reactions along with a selection of Suzuki cross-coupling reactions. We are currently exploring nucleophilic aromatic substitution, Sonogashira coupling, DESI-guided flow synthesis, and green chemistry approaches.

Publications

- Wleklinski, M.; Loren, B. P.; Ferreira, C. R.; Jaman, Z.; Avramova, L.; Sobreira, T. J. P.; Thompson, D. H.; and Cooks R. G., High throughput reaction screening using desorption electrospray ionization mass spectrometry. Chem. Sci. 2018, 9, 1647-1653.